Services

Optimal Conditions

Temperature Control: Maintain a consistent temperature between 0°C to 4°C (32°F to 39°F) for most fruits and vegetables. Specific items may require different temperatures, so it’s essential to monitor and adjust accordingly1

Humidity Control: Keep relative humidity levels between 85% to 95% to prevent dehydration and maintain the freshness of produce2. High humidity is crucial for leafy greens and other moisture-sensitive items.

Air Circulation: Ensure proper air circulation within the storage chambers to maintain uniform temperature and humidity levels. This helps in preventing hot or cold spots and reduces the risk of spoilage3.

Ethylene Management: Some fruits produce ethylene gas, which can accelerate ripening and spoilage of other produce. Store ethylene-producing fruits like apples and bananas separately from ethylene-sensitive items1.

Sanitation: Regularly clean and sanitize the storage areas to prevent mold, bacteria, and pest infestations. This includes cleaning floors, walls, and equipment.

Advantages of Grading

From safety protocols to efficient inventory management practices.

1.Grading before sale enables farmers to get a higher price for their produce.

2.Grading facilitates marketing, for the size, colour, qualities and other designs of the produce.

3.Grading helps consumer to get standard quality products at fair prices.

4. Constraints of manual grading system:

- More time consuming and therefore demand not satisfied.

- Inherently unreliable due to its subjective nature.

- Unhygienic conditions of manual grading have caused a reduction of exported product.

Thus grading of product is beneficial to all sections of society , i.e., the producers, traders and consumers.

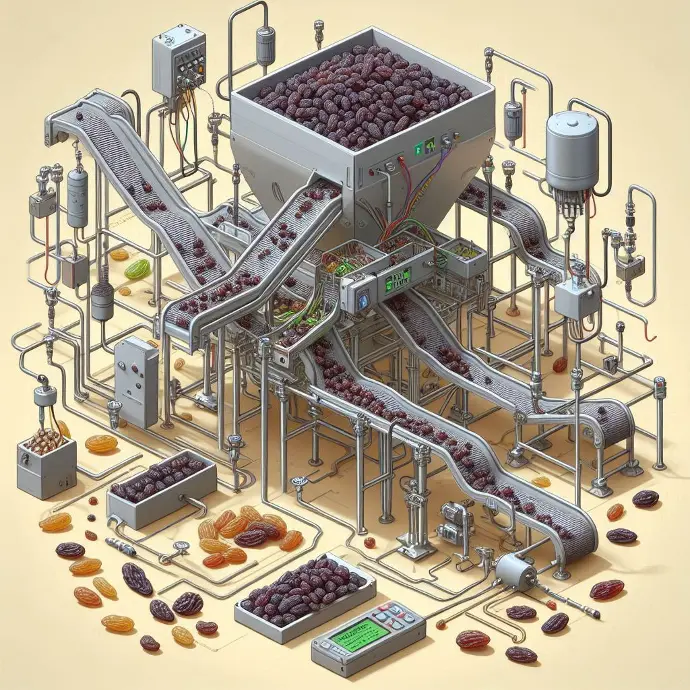

Design and Fabrication of sorter

Color and size are the most important features for accurate grading of bulk raisins. Accordingly , a machine vision system for grading raisins by color and size features has been designed and implemented. The schematic of the prototype sorter is shown above

Software Component Description:

The software part of the machine consists of an image-processing program, which operates through a Graphical User Interface (GUI). Its most important tasks are:

Sending Controlling Commands: The GUI sends controlling commands to the microcontroller via the serial port.

Addressing Virtual Positions: It maps the virtual position of values in the computer to the corresponding real positions of the machine.

Observing and Representing Activities: The program observes the activities and the opening of values, and compares them to represent the performance of a leader during the desired processes.